- Home

- About us

-

Product

-

ED series screw press

-

DP series screw press

-

DW series screw press

-

SLS series screw press

-

SDM series screw press

-

FF series Fiber Filters

-

ED series screw press

-

Industries

-

Food and Beverage Industry

-

Plant Extracts

-

Pulp and Paper Industry

-

Organic waste and food waste

-

Biological raw materials and waste residues

-

Solid-Liquid Separation Industry

-

Fiber filtration

-

Sludge Dewatering

-

Food and Beverage Industry

-

News

-

Videos

-

Customer case

-

Fruit Juice and Beverage Industry

-

Plant Extract Industry

-

Pulp and Paper Industry

-

Organic Waste and Food Waste Industry

-

Biological Raw Materials Waste Residue Industry

-

Solid-Liquid Separation Industry

-

Sludge Dewatering Industry

-

Fruit Juice and Beverage Industry

- Contact us

Product Description

The DP Series Screw Press is specifically engineered for pulp dewatering applications. This high-performance equipment is tailored for the paper and pulp industry, effectively removing water from pulp to optimize processing efficiency. Featuring a durable screw design, the DP Series delivers consistent dewatering results, reducing moisture content and enhancing productivity in pulp production workflows.

Applicable Industry

Pulp and papermaking, pulp dewatering, pulping, straw pulp, wood pulp, bamboo pulp, chemical pulp, cotton pulp, wood fiber, straw, bagasse paper mill, pre-steaming screw, paper recycling, pressing wood knots and sawdust, double-screw press, black liquor extraction, pulp deinking, virgin fiber mill, sawdust, tobacco paper mill, double-screw press, reaction tower, pressing dilute fluid, raw material thickening suitable for chemical pulp, chemi-mechanical pulp, waste paper pulp, poplar chemi-mechanical pulp, eucalyptus chemi-mechanical pulp, bamboo-wood-straw pulp residue fiber, reed and other raw materials for dewatering and concentration enhancement, washing, concentration, black liquor extraction. Multiple units can be connected in series for better extraction effect. Mixed raw materials such as short fibers, bamboo fibers, wood fibers, and long fibers. All can meet the process requirements for washing, concentration and dewatering, and concentration enhancement.

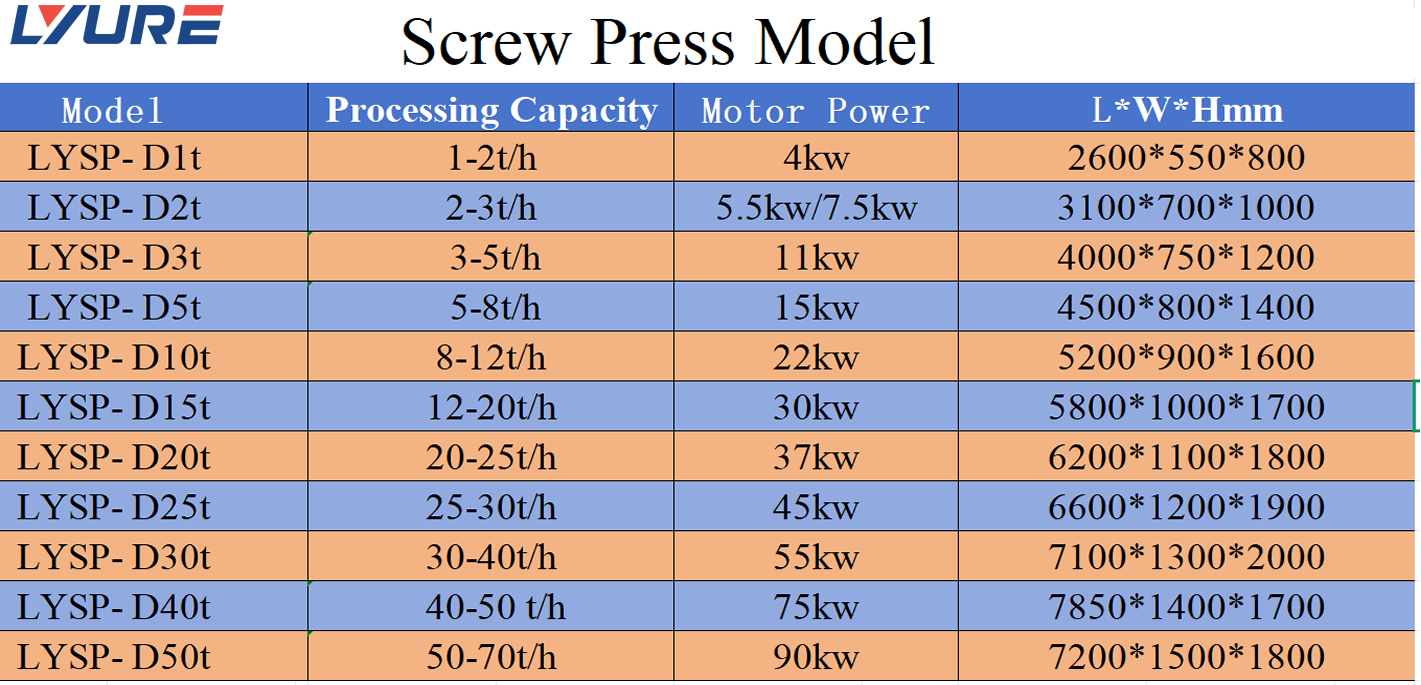

Specifications

FESTO Cylinder

ABB Motor

SEW Motor

WNM Motor

Siemens Motor

SKF bearing

Product details

Frequency converterg

motor

reducer

couplin

Inlet section

Pre-filter segment

Filter segment

Compression segment

Outlet backpressure section

Johnson Screen & Circular hole screen

Air cylinder

Cone disc

Customized products

Different materials can be selected according to different materials, and products can be customized according to customer needs.

Our services at a glance ...

Years Experience

Industries Served

Factories Built

-

How easy is it to operate and maintain the machine?Screw press machines are generally user-friendly, with simple controls and a robust design for continuous operation. They come with manuals and often video tutorials for setup, operation, and troubleshooting. Maintenance involves regular lubrication, checking the screw and barrel for wear, and cleaning after use, which is straightforward due to accessible components. Suppliers typically offer technical support to ensure smooth operation.

-

How easy is it to operate and maintain the spiral press machine?The machine is designed for simple operation, often requiring minimal training. Basic models are manually operated, while advanced ones feature automatic temperature control and filtration systems. Maintenance involves regular cleaning of the screw and press chamber, lubrication of moving parts, and occasional replacement of worn components, all of which are straightforward with provided instructions.

-

What is the capacity of the spiral press machine?Capacities vary by model. Small-scale machines can process 1-10 tons of material per day, while larger industrial models can handle 20-50 tons or more. For instance, a common small-scale machine might process 500kg per hour, making it ideal for home or small business use, whereas larger units suit commercial production.

-

Can the machine handle both cold and hot pressing?solutionsMany models support both, with adjustable temperature settings. Cold pressing preserves nutrients, while hot pressing increases yield. Verify this feature with the supplier.

-

Can the machine be customized for specific needs?Yes, many suppliers offer customization options like capacity, screw design, or additional filtration. Discuss your requirements upfront.

Phone

Phone