High-end screw press dehydration equipment manufacturer

We are Lyure Machinery

Pulp and Paper Industry

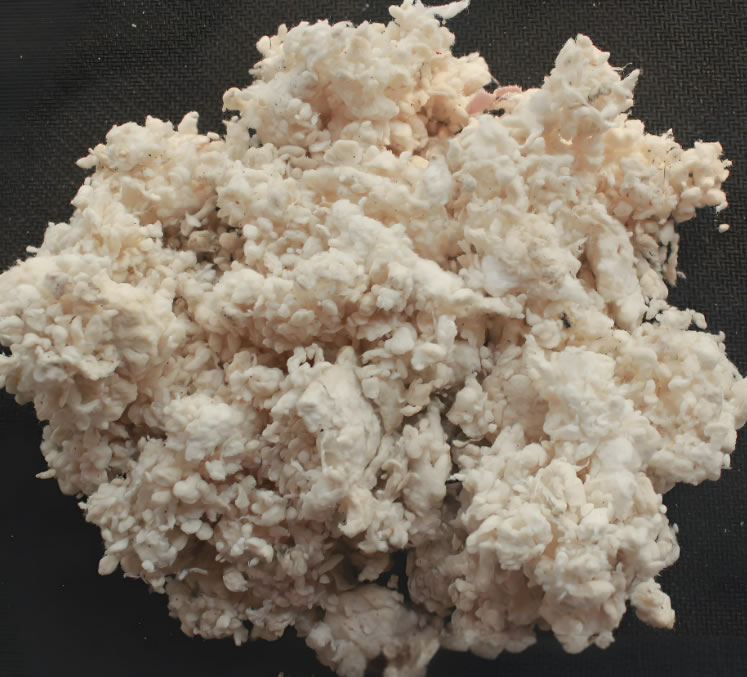

The screw press is a vital piece of equipment in the pulp and paper industry, primarily used for dewatering and thickening pulp. It operates by applying mechanical pressure through a rotating screw within a perforated or slotted screen, efficiently separating water from the pulp fibers. This process enhances pulp consistency, reducing water content for subsequent processing stages like drying or refining. Screw presses are valued for their high throughput, energy efficiency, and ability to handle various pulp types, contributing to cost-effective and sustainable production in modern paper manufacturing.

Pulp and papermaking, pulp dehydration, pulping, straw pulp, wood and bamboo pulp, chemical pulp, cotton pulp, wood fiber, straw, bagasse, pulp mill, paper mill, pre-cooking, continuous reaction, cooking spiral, pressing wood knots and sawdust, double screw squeezer, night extraction. Suitable for dehydration, concentration, washing, concentration, and black liquor extraction of chemical pulp, chemical pulp, waste paper pulp, poplar chemical mechanical pulp, eucalyptus chemical mechanical pulp, bamboo, wood, grass pulp residue fiber, reed and other raw materials. The extraction effect is better if multiple units are connected in series. Mixed raw materials such as short fibers, bamboo fibers, wood fibers and long fibers. All can meet the process requirements for reaction, washing, concentration and dehydration, concentration, pulp deinking, original fiber plants, sawdust, tobacco paper mills.

Pulp and papermaking, pulp dehydration, pulping, straw pulp, wood and bamboo pulp, chemical pulp, cotton pulp, wood fiber, straw, bagasse, pulp mill, paper mill, pre-cooking, continuous reaction, cooking spiral, pressing wood knots and sawdust, double screw squeezer, night extraction. Suitable for dehydration, concentration, washing, concentration, and black liquor extraction of chemical pulp, chemical pulp, waste paper pulp, poplar chemical mechanical pulp, eucalyptus chemical mechanical pulp, bamboo, wood, grass pulp residue fiber, reed and other raw materials. The extraction effect is better if multiple units are connected in series. Mixed raw materials such as short fibers, bamboo fibers, wood fibers and long fibers. All can meet the process requirements for reaction, washing, concentration and dehydration, concentration, pulp deinking, original fiber plants, sawdust, tobacco paper mills.